Ultrasonic welding technology is a common technology in the field of plastic welding because of its economic, reliable, and easy automation integration. Unlike traditional heat sources, which generate heat in direct contact with plastics, ultrasonic welding generates heat through friction.

1. Amplitude, frequency and wavelength

In ultrasonic welding, longitudinal waves are transmitted at high frequencies, producing low-amplitude mechanical vibrations. The electrical energy of the welding machine is converted into mechanical energy. In order to understand the relationship between amplitude, frequency, and wavelength, and how they relate to heat production, we need to look at the main components of an ultrasonic welding machine.

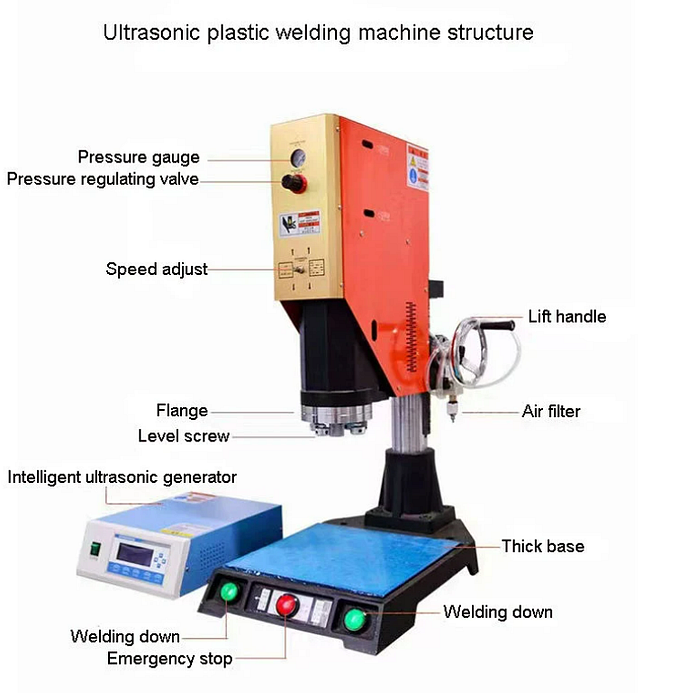

The main components of an ultrasonic welding machine are a power generator, transducer, booster, and welding horn. The power generator converts 50–60Hz, 120V/240V power to 1300V power running at 20–40Khz. This energy is supplied to a transducer, which uses a disk-shaped piezoelectric ceramic to convert electrical energy into mechanical vibrations.

The converter passes the vibrations to the booster. The booster amplifies the amplitude of the ultrasonic wave and continues to transmit it to the welding horn. The welding horn continues to amplify the amplitude of the ultrasonic waves and makes contact with the part.

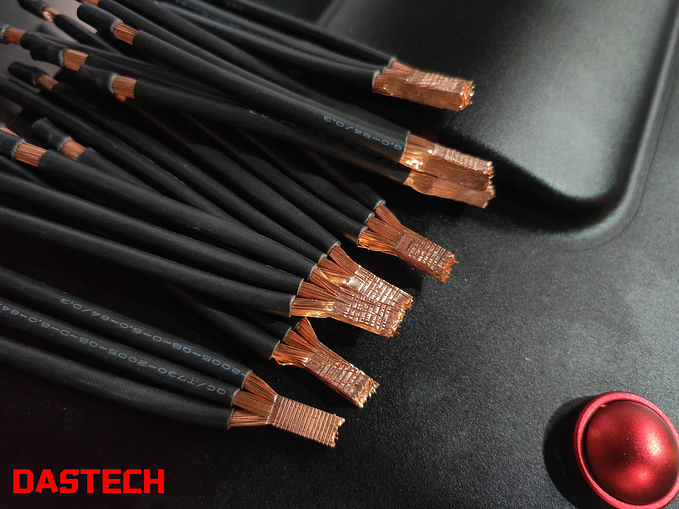

Ultimately, the energy is transferred to the welded rib locations of the two parts. Because the welding ribs are designed with sharp points, the energy is concentrated at the sharp points, and friction and heat are generated under pressure. This heat is generated by two types of friction, one is the surface friction between the upper and lower part materials, and the other is the intermolecular friction within the material. It is the heat generated by friction that causes the upper and lower parts to melt and join together at the welding location.

2. Heating Rate

For the same material, three factors determine the heating rate: frequency, amplitude, and welding pressure. For existing equipment, such as 15Khz, 20Khz, 30Khz, or 40Khz machines, the frequency is fixed. So the heating rate can usually be changed with the welding pressure. Generally, the greater the pressure, the faster the heating rate. In addition, you can also change the amplitude. Like the pressure, the greater the amplitude, the faster the heating rate.

Of course, excessive pressure and amplitude will also have adverse effects on welding quality, such as material degradation, cracks, and flash. Therefore, ultrasonic welding requires a process of process parameter optimization. After the parameters are determined, the welding process can achieve a stable output with fast speed and high welding strength. This is why ultrasonic welding is widely used in mass production.

3. Time, Distance, Power and Energy

The amount of heat required for welding depends on the material type, weld design, and equipment specifications. The traditional method of controlling heat is to weld via a time pattern. However, today’s ultrasonic welding equipment can often also set and monitor welding distance, power, and energy.

Properly trained operators can also adjust parameters according to actual conditions and different materials to obtain consistent welding results. This also greatly improves the flexibility and reliability of welding.